GR-EP-45ENC 45mm 12V 20W Planetary Gearmotor with Encoder

The GR-EP-45ENC is the encoder-equipped brother of the GR-EP-45E gearmotor model. It is a mid-powered 12V DC motor and planetary (epicyclic) gearbox combination, available with 5 different gearbox ratios to provide a wide variety of speed and torque outputs from the ~20W motor: 3.7:1, 19.2:1, 50.9:1, 99.5:1, 369:1.

The motor may be operated at anywhere between 3-12V DC. Operating characteristics are given for operation at 12V or 6V further down the page.

The output shaft is 10mm diameter, with a 4mm wide slot for easy mounting. Each motor is supplied with a 4-pin wired connector for use with the encoder.

Availability: IN STOCK

SKU: GR-EP-45ENC_99.5

Couldn't load pickup availability

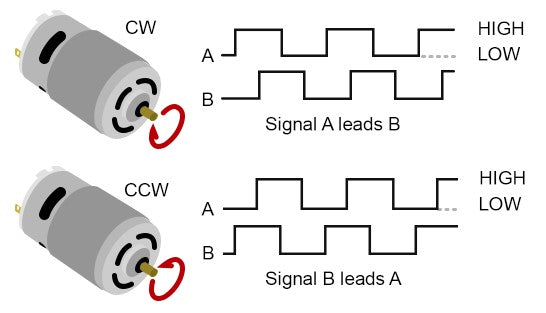

Integrated Encoder

User Advice

Compliance

Motor Dimensions

For the diagram below the dimension L is 33.6mm for the 3.7:1 gearbox, 44.9mm for the 19.2:1 gearbox, 56.2mm for the 50.9:1 and 99.5:1 gearboxes and 67.5mm for the 188:1 or 369:1 gearbox. Please allow for +/-1mm on overall length. CAD models are available, please contact us for a copy.

Gearbox Build Detail

With 3.7:1 gearbox: 45mm diameter, 154.1mm long

With 19.2:1 gearbox: 45mm diameter, 165.4mm long

With 50.9:1 gearbox: 45mm diameter, 176.7mm long

With 99.5:1 gearbox: 45mm diameter, 176.7mm long

With 188:1 gearbox: 45mm diameter, 188mm long

With 369:1 gearbox: 45mm diameter, 188mm long

The 3.7:1 gearbox has one reduction stage, the 19.2:1 has two reduction stages, the 50.9:1 and 99.5:1 each have three stages, and the 188:1 and 369:1 each have four gearbox stages.

Apart from the 3.7:1 ratio which has all-metal gears, all other ratios have POM planet gears on their first (input) stage for lower-noise operation. The subsequent gearbox stages on the 19.2:1 onwards all use metal gears.

All gears are 0.6M pitch, the input pinion has 17 teeth.

19.2:1 = 19 38⁄187 :1

50.9:1 = 50 4397⁄4913 :1

99.5:1 = 99 1044⁄2057 :1

188:1 = 188.611 :1

369:1 = 369.763 :1

Features a 20mm long, 4mm wide and 2.5mm deep rectangular keyway.

With 3.7:1 gearbox: 650g

With 19.2:1 gearbox: 760g

With 50.9:1 gearbox: 875g

With 99.5:1 gearbox: 875g

With 369:1 gearbox: 990g

The breaking (maximum rated) output torque of the 3.7:1 ratio gearbox is 60kg-cm, be careful to avoid shock/impact loads that could exceed this.

Please be aware that some of the values above are extrapolated from other measurements and it's normal for there to be a small degree of variance from motor to motor, you should allow for a safety factor of at least 10% above/below the given values when designing for your application. The output figures provided are based upon an average 90% gearbox efficiency for the 3.7:1 ratio gearbox. Be sure that any equipment that you use with the motor (power source and controller) is capable of handling the currents that the motor may demand, whilst also being able to limit the current to protect the motor in the event of it stalling.

The breaking (maximum rated) output torque of the 19.2:1 ratio gearbox is 180kg-cm, be careful to avoid shock/impact loads that could exceed this.

Please be aware that some of the values above are extrapolated from other measurements and it's normal for there to be a small degree of variance from motor to motor, you should allow for a safety factor of at least 10% above/below the given values when designing for your application. The output figures provided are based upon an average 81% gearbox efficiency for the 19.2:1 ratio gearbox. Be sure that any equipment that you use with the motor (power source and controller) is capable of handling the currents that the motor may demand, whilst also being able to limit the current to protect the motor in the event of it stalling.

The breaking (maximum rated) output torque of the 50.9:1 ratio gearbox is 300kg-cm, be careful to avoid shock/impact loads that could exceed this.

Please be aware that some of the values above are extrapolated from other measurements and it's normal for there to be a small degree of variance from motor to motor, you should allow for a safety factor of at least 10% above/below the given values when designing for your application. The output figures provided are based upon an average 73% gearbox efficiency for the 50.9:1 ratio gearbox. Be sure that any equipment that you use with the motor (power source and controller) is capable of handling the currents that the motor may demand, whilst also being able to limit the current to protect the motor in the event of it stalling.

The breaking (maximum rated) output torque of the 99.5:1 ratio gearbox is 300kg-cm, be careful to avoid shock/impact loads that could exceed this.

Please be aware that some of the values above are extrapolated from other measurements and it's normal for there to be a small degree of variance from motor to motor, you should allow for a safety factor of at least 10% above/below the given values when designing for your application. The output figures provided are based upon an average 73% gearbox efficiency for the 99.5:1 ratio gearbox. Be sure that any equipment that you use with the motor (power source and controller) is capable of handling the currents that the motor may demand, whilst also being able to limit the current to protect the motor in the event of it stalling.

The breaking (maximum rated) output torque of the 188:1 ratio gearbox is 300kg-cm. Ensure that the motor output is limited to well below the values highlighted in red, to prevent the motor from damaging itself by exceeding this maximum load.

Please be aware that some of the values above are extrapolated from other measurements and it's normal for there to be a small degree of variance from motor to motor, you should allow for a safety factor of at least 10% above/below the given values when designing for your application. The output figures provided are based upon an average 65% gearbox efficiency for the 188:1 ratio gearbox. Be sure that any equipment that you use with the motor (power source and controller) is capable of handling the currents that the motor may demand, whilst also being able to limit the current to protect the motor in the event of it stalling.

The breaking (maximum rated) output torque of the 369:1 ratio gearbox is 300kg-cm. Ensure that the motor output is limited to well below the values highlighted in red, to prevent the motor from damaging itself by exceeding this maximum load.

Please be aware that some of the values above are extrapolated from other measurements and it's normal for there to be a small degree of variance from motor to motor, you should allow for a safety factor of at least 10% above/below the given values when designing for your application. The output figures provided are based upon an average 65% gearbox efficiency for the 369:1 ratio gearbox. Be sure that any equipment that you use with the motor (power source and controller) is capable of handling the currents that the motor may demand, whilst also being able to limit the current to protect the motor in the event of it stalling.