The

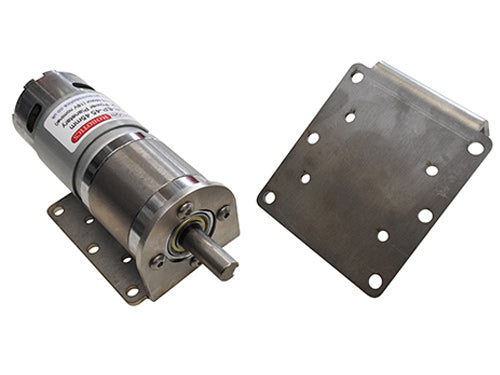

GR-PL45-24 provides a compact and robust electric drive solution, with all-metal gearing and a simple-to-operate 24V-nominal brushed DC motor. A 12V-nominal version is also available, the

GR-PL45-12. It has a 45mm diameter cross section, with a longer body the larger the gearbox ratio (see drawing below). A PDF model reference sheet

is available here.

The motor is a useful size for medium-scale automation, special effects and industrial processes. It is more powerful than most common 'hobby' gearmotors of 25mm or 36mm size, and yet not so powerful as to demand more-expensive high-current power & control circuitry. It is also able to handle much greater output torque than model gearmotors with smaller gears and/or non-planetary gearboxes.

Two copper tabs at the back of the motor body can be used to solder or crimp wires to (the tabs are suitable for 4.8mm female spade connectors). If you require a custom wiring or control option

please contact us to discuss specifications and pricing.

CAD models are available, please contact us for a copy, mentioning the gearbox ratio(s) that you require models for.

Motor Performance

|

GR-PL45-24 Performance, at 24V DC

|

|---|

| Gearbox |

No-Load Speed,

Current |

Maximum Continuous

Speed & Torque at 1.1A |

Maximum 20% Duty (20s)

Speed & Torque at 3.0A |

Peak Torque

at Stall, 12.5A |

Maximum Safe

Current |

|---|

| Ratio |

Efficiency |

rpm |

Amps |

rpm |

Torque, kg-cm |

rpm |

kg-cm |

kg-cm |

Amps |

|---|

| 19.2:1 |

81% |

309 |

0.35 |

289 |

4.68 |

239 |

16.6 |

75.9 |

- |

|---|

| 50.9:1 |

73% |

117 |

0.4 |

110 |

10.4 |

90.7 |

38.8 |

181 |

- |

|---|

| 99.5:1 |

73% |

59.6 |

0.4 |

56.0 |

20.4 |

46.4 |

75.8 |

353 |

10.7 |

|---|

| 188:1 |

65% |

31.6 |

0.4 |

29.7 |

34.4 |

24.6 |

128 |

594 |

6.5 |

|---|

| 369:1 |

65% |

16.1 |

0.4 |

15.1 |

67.4 |

12.5 |

250 |

1165 |

3.5 |

|---|

| 997:1 |

59% |

6.0 |

0.45 |

5.7 |

154 |

4.7 |

602 |

2846 |

1.7 |

|---|

The breaking (absolute maximum) output torque of the gearbox is 300kg-cm. You must avoid shock/impact loads that might exceed this.

For the higher-ratio gearboxes, the maximum safe current values must not be exceeded (the values highlighted in Red in the right-hand column), or else the motor can generate enough torque to permanently damage the gearbox.

Be aware that some of the values above are extrapolated from other measurements and it's normal for there to be some variance from motor to motor, you should allow for a safety factor of at least 10% above/below the given values when designing for your application. Motor performance may vary if driven via PWM, due to interactions with the filtering components inside the motor (this will depend on the supply voltage and PWM frequency). Be sure that any equipment that you use with the motor (power source and controller) is capable of handling the currents that the motor may demand, whilst also being able to limit the current to protect the motor in the event of an overload. Warning: Continuous operation above 1.1A is likely to lead to overheating. 20% duty figures provided are for maximum 20 second cycles (20sec on / 80sec off).

User Advice

This motor operates like any other DC motor and so may be used at voltages other than the nominal 24V with changed operating characteristics (please be aware that the warranty does not cover operation above 24V, which is likely to shorten the lifespan). Reducing the voltage reaching the motor will decrease the output speed and current for a given load, while increasing the voltage will increase the speed and the current.

To change the output direction (clockwise/anti-clockwise), swap the polarity of the power to the motor contacts (invert positive and negative). This is usually done via a controller, for example one of our

GR-MOT1 motor drivers.

You should fit circuit protection to protect both the motor from stalling/overheating and your power source from overload.

At a minimum this would be an appropriately rated fuse in series with each motor, but we would recommend fast-response adjustable current limiting, such as that offered by the

GR-MOT1, as this type of overcurrent protection is normally much more consistent, faster in its response, and far more convenient to use (with automatic resetting) when compared with a fuse.

Make sure to read the performance table above, to help identify which of the gearbox options is suitable for your application. If you're unsure about selecting an appropriate motor for the task please

send details of your application to us and we'll guide you through the options.

Compliance

The motor has been designed with electrical noise (EMI) suppression built-in, and has been demonstrated as being able to pass EMC standard EN 61000-6-3:2021. Bear in mind that EMC compliance should be re-assessed in end applications as it is dependent upon the connected power & control hardware. The motor is RoHS compliant. A UKCA declaration of conformity is available upon request.

Motor Dimensions

For the drawing below the Gearbox Length dimension L is 44.9mm for the 19.2:1 gearbox, 56.2mm for the 50.9:1 and 99.5:1 gearboxes, 67.5mm for the 188:1 and 369:1 gearboxes and 78.8mm for the 977:1 gearbox.

Allow for +/-1mm on overall length, other body dimensions are to +/-0.5mm, while the shaft diameter is to h8 tolerance, and the keyway width is to +/-0.03mm.

Gearbox Build Detail

Mounting

Four M4 x 9mm threaded holes on the front face of the gearbox (see above diagram). PCD 35mm.

Gearbox type

Planetary/epicyclic, with three 'planet' gears per stage, on large carrier pins. The 19.2:1 gearbox has two reduction stages, the 50.9:1 and 99.5:1 have three stages, the 188:1 and 369:1 have four stages and the 977:1 has five reduction stages.

Operating temperature

-10°C ~ 40°C

Output shaft

10mm by 24mm long steel (40Cr, 25-26 HRC) shaft, nickel plated for corrosion resistance. Features a 20mm long, 4mm wide and 2.5mm deep rectangular keyway

Shaft support

Dual 10mm deep groove roller bearings (6900Z)

Weight

With 19.2:1 gearbox: 750g

With 50.9:1 or 99.5:1 gearbox: 860g

With 188:1 or 369:1 gearbox: 980g

With 977:1 gearbox: 1090g