Download Reference Sheet

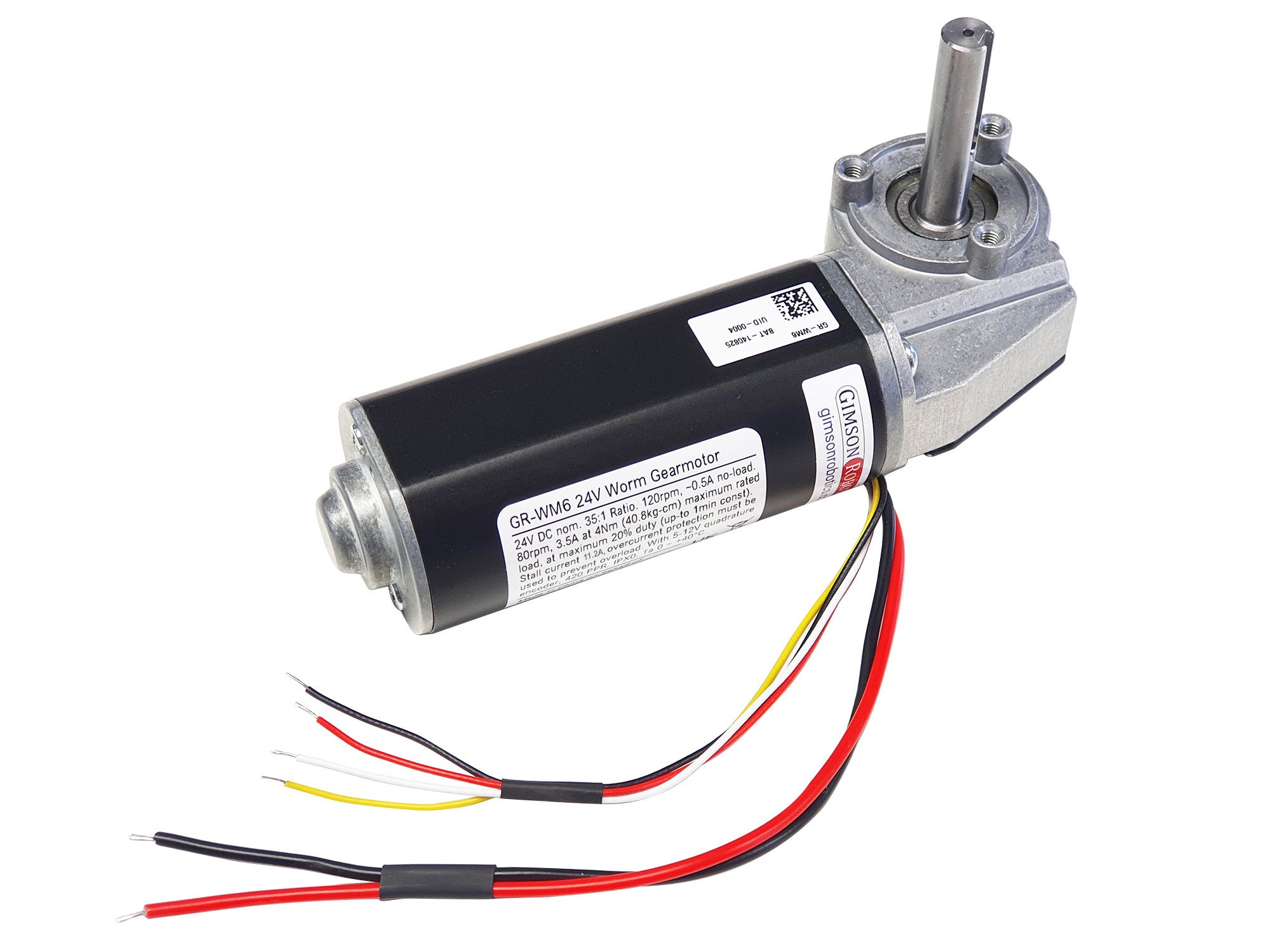

GR-WM6

The

GR-WM6 is a geared motor designed from the outset for low-noise operation. The single-stage 35:1 worm gearbox, with a polymer worm-wheel, provides high torque yet quiet operation. This makes it ideal for intermittent load applications (occasional movements, due to the 20% duty cycle limitation) where minimising generated sound is an important design factor. We recommend that it is used with fast overcurrent-response motor controllers, such as the

GR-MOT1 or the

GR-SYNC, since the gearbox is more susceptible to damage due to overloading than other gearbox types.

The motor has been assessed to EMC standards EN 61000-6-3:2021 and EN 61000-6-1:2019, and it is RoHS compliant. Bear in mind that EMC compliance should be re-assessed in end applications as it is dependent upon the connected power & control hardware.

Please consult the product reference sheet for more details.

CAD models are available, please

contact us for a copy.

Integrated Encoder

The motor has a hall-sensor based quadrature encoder mounted internally (tracking the motor shaft). The encoder is not required for operation (and won't affect operation if left disconnected), but for many projects it provides very useful feedback of the speed, and relative position, of the motor. It is accessed via the thinner Red, Black, White and Yellow wires to the motor. Positive power for the encoder (<10mA) should be provided to the Red lead (+5V VCC), and Black should be connected to ground/GND. Ensure that the correct polarity connection is made to these wires.

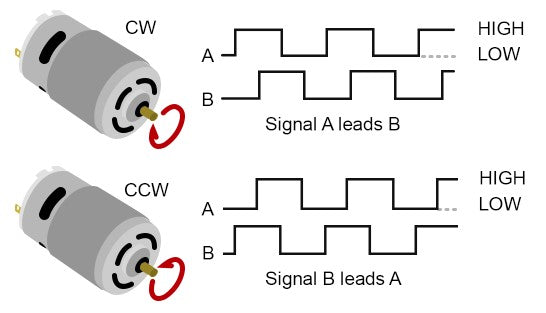

It has a dual-channel output (channel A White lead, Channel B Yellow lead), with 6 complete pulses per channel, per rotation of the motor itself (12 PPR across both channels); or 35 x 6 = 210 pulses, per channel, of the output shaft given the 35:1 gearbox ratio. One of the channels is out of phase with the other, as such it is possible to tell both the speed (from pulse frequency) and direction (by reading the pulses of one channel and comparing it to the other) of the motor. The nature of the signals that are generated is illustrated below.

Cable & Connector Options

The motor is supplied with ~150mm long exposed-end (tinned) cables as standard (as pictured above). An option is provided above to include either a 0.3m or a 1m long cable with a 6-pin Male connector. If a non-standard cable option is selected please allow an additional 2 working days for your order to be processed as cable customisations are prepared to-order. If a 6-pin Male connector option is added, it allows the motor to be connected directly in to the

GR-SYNC motor controller.

User Advice

This motor operates like any other DC motor and so may be used at voltages other than the nominal 24V with changed operating characteristics (please be aware that the warranty does not cover operation above 24V, which is likely to shorten the lifespan). Reducing the voltage reaching the motor will decrease the output speed and the torque, while increasing the voltage will increase the speed and the torque (torque is directly related to current).

To change the direction of rotation invert the polarity of the DC supply to the two motor wires (invert positive and negative). This is usually done via a control switch or controller, for example our

GR-MOT1 or

GR-SYNC controllers handle polarity inversion themselves.

You must fit circuit protection to protect both the motor and your power source/cabling from damage due to overload. Our GR-MOT1 and GR-SYNC controllers can provide suitable protection, when adjusted appropriately to each application/load.

Make sure to read the performance tables for the motor below (or

on the reference sheet), so that you have an understanding of the torque, current and speed that you can expect from it. If you're unsure about selecting the appropriate motor for the task please send application (loading) details over to us and we'll talk through the options.

Motor Dimensions

Please see drawing below. CAD models are available, please contact us for a copy.

Construction Detail

Mounting

3off M4 tapped holes, 6mm depth each. 35.8mm PCD (about the output shaft)

Overall size

Approximately 159mm long, 67mm tall, 42mm deep (excluding output shaft).

Body material

Cast aluminium gearbox housing with black painted steel motor casing.

Gearbox type

Single-stage worm transmission with steel worm gear and polymer worm-wheel.

Maximum gearbox torque

Up-to 40.8kg-cm (4Nm). Be aware that the motor itself is easily able to generate greater torque than this, so you should ensure that there is overcurrent protection, and/or a mechanical clutch, in place to prevent it exceeding this mechanical limit.

Operating temperature

Ambient: 0°C ~ +40°C. The motor is not suitable for unprotected outdoor use. Motor insulation class B (up-to 130°C hot spot temperature).

Shaft type

10mm diameter by 35mm long (beyond mounting face/surface).

Features a 26mm long, 4mm wide and ~2.2mm deep rectangular keyway.

Shaft support

16001Z 12mm ID deep groove ball bearing, with 12mm ID x 6mm bronze bushing

Weight

795g, excluding optional lead/connector additions.

Operating characteristics (values at output from gearbox)

No-load speed

120rpm

60rpm

No-load current

0.5A

0.4A

Continuous rated torque, speed (maximum 20% duty, up-to 1-minute continuous)

40.8kg-cm, 80rpm

40.8kg-cm, 27rpm

Rated load current

3.5A

3.5A

The gearbox is designed for low-noise operation with a polymer worm-wheel, however this does mean that it is more-sensitive to overheating and also to overloading (especially impact loads) than other gearbox types, as such the maximum duty cycle and load torque ratings must be adhered to strictly, otherwise the gearbox may fail. We recommend using a controller with fast-response current limiting, such as the GR-MOT1 or the GR-SYNC.

Please be aware that it is normal for there to be some variance in performance from motor to motor, it is advisable to allow for a minimum safety factor of 10% above/below the given values when designing for your application. You should also factor in acceleration torque, as this can sometimes be much greater than steady-state load torque, especially if accelerating quickly (for example, with no ramping).

Be sure that any equipment that you use with the motor (power source and controller) is capable of handling the currents that the motor may demand, whilst also being able to limit the current to protect the motor in the event of the load increasing beyond the rated values.